We supply aseptic motors and the drive package ASEPTICplus® specifically for use in hygienic areas. Technology that is tailored perfectly to sensitive production areas for the food, cosmetics and pharmaceutical industries.

Aseptic motors: Tidy and easy-to-clean

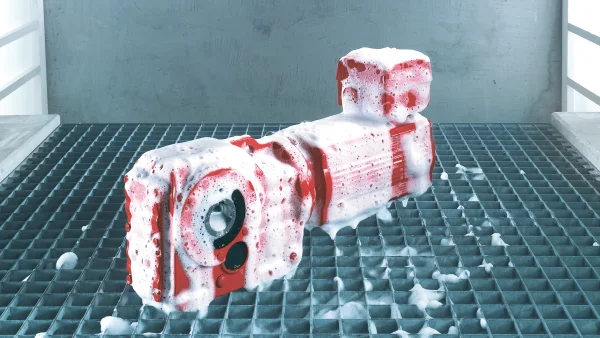

We develop and produce aseptic motors with special equipment for hygienically sensitive production areas. The DAS.. series is ideal for use in your sensitive production areas such as in the pharmaceutical, cosmetics or food and beverage industry. Even if an absolutely clean production environment is prescribed, you can safely use the motors in connection with the drive package ASEPTICplus®.

Two significant properties of the DAS.. series motors are sure to interest you:

1. In contrast to standard motors, which are equipped with cooling fins, the surface of our aseptic motors is as smooth as is possible. This makes them dirt-repellent.

2. Standard motors have a fan, our motors do not: they are convection-cooled. This means that they cause no air turbulences and, consequently, do not distribute any germs and bacteria.

The cleaning processes for the production system that are essential in those types of production areas are just as problem-free and practicable. Equipped with the appropriate surface and corrosion protection measures, you can safely apply aggressive cleaning agents and disinfectants with these motors or the drive package ASEPTICplus® . This is because the painting and materials used withstand the regular cleaning procedures.

So put your trust in drive technology for hygienic areas made by SEW-EURODRIVE.

Get in touch with us.

- Our experts know your industry and its requirements.

- Our global network ensures we are close wherever and whenever you need us.

- We have the know-how and tools to provide optimum advice and support.

Your benefits

-

Avoid dust

as the motors do not have any cooling fins and no dirt sticks to their almost entirely flat surface. -

Stop germ distribution

because the aseptic motors are convection-cooled they cause no air turbulences and, consequently, do not distribute germs and bacteria.

Features

Be it production, filling or packaging: with the aseptic motors of the DAS.. series and the drive package ASEPTICplus® you can reliably operate your machines or systems:

- DAS.. series for dry hygienic areas:

- Fanless motor, pure convection cooling, resulting in zero air turbulences

- Smooth surfaces; no dirt build-up

- Enclosure IP66 (brakemotors IP65)

- KS internal coating as motor corrosion protection

- Surface protection OS2 to OS4 possible

- Motor protection thermistor in thermal class F, TH optional (thermocontact)

- IS plug connector

- Drive package ASEPTICplus® with additional preventive measures for use in hygienic production areas:

- Motors in degree of protection IP69K (brakemotors IP65)

- Surface protection OS4

- Contour recesses filled with natural rubber

- Double oil seals (if possible) at the output made of FKM

- Stainless steel breather valve

- Pressure compensation membrane on the motor terminal box

- Cable entry with screw plugs made of stainless steel

- Gear unit output shaft made of stainless steel as solid shaft, hollow shaft with key or TorqLOC® for gear unit types: R17-97, F37-97, K37-97, S37-97 and W30

- All fastening parts at the output shaft, such as screws, keys, shrink disk, etc., made of stainless steel

Technical data

Aseptic motors of the DAS.. series

| Type | Power in kW in duty type | |||

|---|---|---|---|---|

| S1 = Continuous duty | S3 = Intermittent duty | |||

| 60 % | 40 % | 25 % | ||

| DAS80K4 |

0.25 |

0.3 |

0.37 |

0.55 |

| DAS80N4 |

0.3 |

0.45 |

0.55 |

0.75 |

| DAS90S4 |

0.55 |

0.75 |

0.9 |

1.1 |

| DAS90L4 |

0.75 |

0.98 |

1.1 |

1.5 |

| DAS100M4 |

1.1 |

1.35 |

1.7 |

2.2 |

| DAS100L4 | 1.5 | 1.85 | 2.3 | 3.0 |

Ambient conditions

Always the right choice

The drive technology used encounters special ambient conditions In hygienic areas, and should therefore be resistant to aggressive cleaning agents and disinfectants. You are making the right choice with our DAS.. series motors because they are protected against:

- Moisture

- Water jets

- Dirt

- Oils

- Bacteria

- Cleaning agents

- Chemicals

- Change in temperature

- A compatibility test for cleaning agents made by ECOLAB was performed, documented and can be requested

Areas of application

- Food and beverage industry

- Chemicals and pharmaceuticals industry

- Applications in dry hygienic areas e.g.

- PET bottle conveyor belts

- Applications in hygienic production areas e.g.

- Conveyor belts in meat processing